Restoring a Universal Geneve Medico Compax

Today we will be tackling the restoration of a beautiful Universal Geneve Medico Compax. This watch is powered by the Universal Geneve 285, a solid piece of engineering, including an eight-column pillar wheel design, two button operation and compax design.

The movement looked to be in fairly respectable shape, however, there were a few rusty spots that needed to be tackled. Aside from that, your typical wear and tear for a watch of this age.

Pictured below we can see rust present on the operating lever.

Another issue I uncovered was the side shake of the barrel. It was excessive and it needed to be rectified.

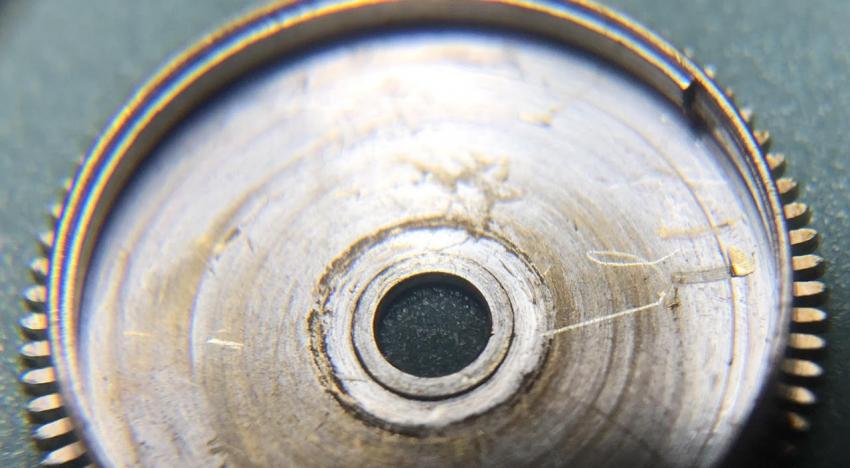

You can see from the below shots that the side of the barrel where the arbour sits is worn and looks a little chewed up. Over time the old lubricants form a grinding paste and cut away at the metal of the barrel.

If barrel side shake is excessive, we start to see amplitude problems. The reason for this is because the hole in the barrel that the arbour sits in is too large. It develops too much room to move, creates a teeter-totter effect and the barrel can then rock back and forth. If will then either touch the mainplate or the barrel bridge which in turn causes the amplitude to drop. This problem doesn’t just affect the barrel though, it then causes the ratchet wheel (which is screwed on to the top of the barrel and winds the mainspring) to rub on the barrel bridge, leading to wear on the ratchet wheel and barrel bridge. Such a problem is a classic example of what can happen if a watch doesn’t have regular servicing.

Apart from the above issues, there were no major problems present other than the standard cleaning, oiling, and adjustments.

Now to get on with the repairs.

First I wanted to tackle the rust and refinishing of the components. Refinishing components can be a very laborious task. It is crucial that when refinishing is undertaken, edges remain sharp. All too often you see rounded edges, whether it be movement components or watch cases. It’s horologically displeasing. While functionally, it won’t have an effect, aesthetically it’s everything. Here we can see the parts after refinishing.

With that taken care of, it was time to tackle the barrel repair.

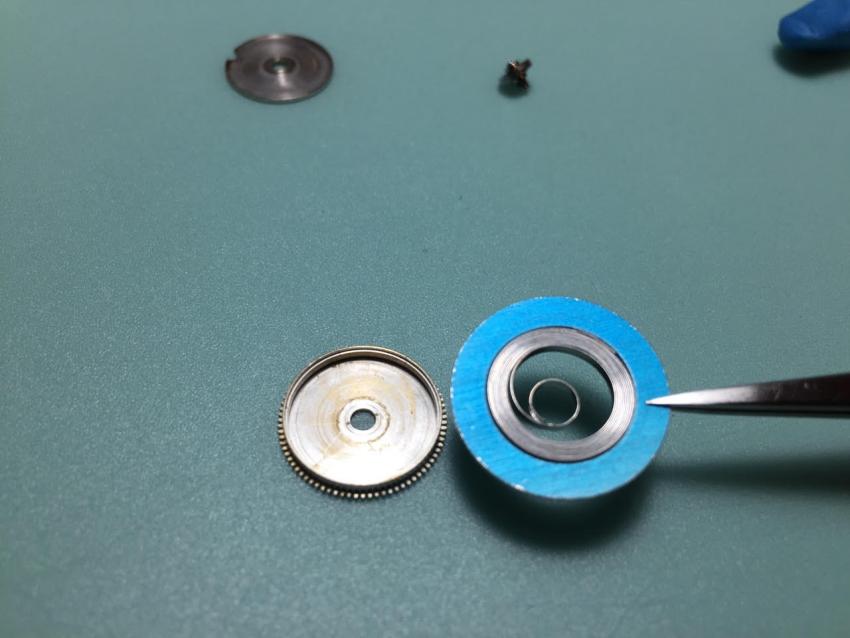

Below you can see the barrel set up in the staking tool. A round punch is used to close the hole. Great care needs to be taken to ensure that the hole isn’t closed too much.

A close-up.

The punch is then lightly tapped with a hammer so that the hole closes up.

Below we can see what the barrel looks like after the repair.

Installing the new mainspring.

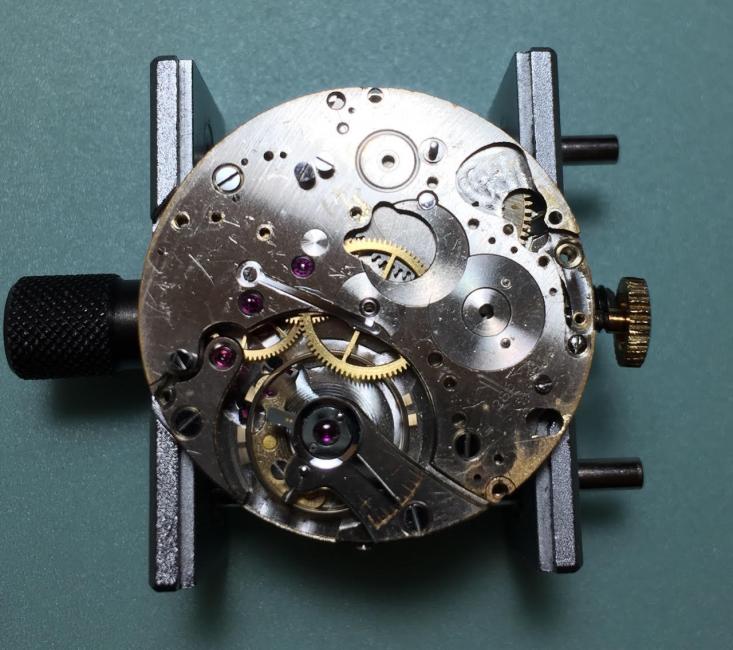

Now on to the assembly of the movement.

Barrel, gear train, escapement and balance wheel assembled. Running nicely now.

Once the chronograph work has been assembled there are a series of checks that need to be made, but we will tackle that in another discussion.

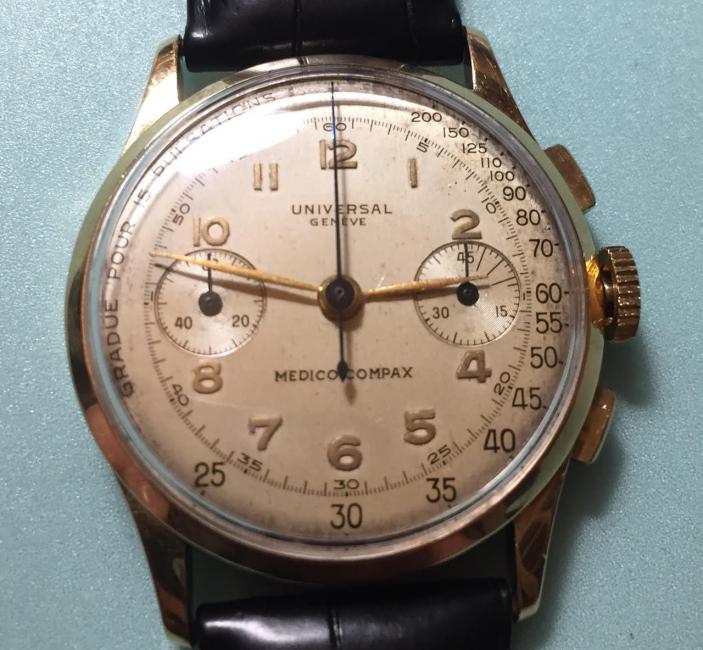

Here you can see when the whole movement is assembled and we have now cased the watch.

The 285 truly is a beautiful piece of engineering. There is nothing I love more than a column wheel chronograph. They are such a pleasure to work on.

The last step that needs to be taken is testing. Testing is such a crucial part or watchmaking. Without it, there is no way to know whether the watch is in tip-top condition. I like to test for about a week to ensure everything is running as it should be. There is no substitute for taking the time to do things properly the first time.

The final product, and another happy watch collector.

Ashton Tracy is a WOSTEP-trained watchmaker with over a decade worth of horological experience. He has worked all over the world repairing everything from Mont Blanc’s to military IWC’s. Currently living in Toronto, Ashton works for one of the major after-sales service centres. In his private workshop, he undertakes vintage restorations and modern servicing after hours.

Website: www.kosmoswatchmaking.ca

Follow him on Instagram @Kosmoswatchmaking

Or add him on Facebook

Kosmos Watchmaking